One of the key advantages of the thread button bit is its versatility. It can be employed in a wide range of drilling applications, from construction sites to underground mines, and from oil and gas exploration to geotechnical investigations. Its ability to handle diverse rock types, from soft to extremely hard, makes it a go-to choice for many industries Its ability to handle diverse rock types, from soft to extremely hard, makes it a go-to choice for many industries

Another notable feature is their durability. Fiberglass ducts are resistant to corrosion, unlike metal ducts that can rust over time. They also withstand extreme temperatures, making them suitable for both heating and cooling applications. Their non-porous surface resists dust accumulation, contributing to cleaner air quality and less frequent maintenance Their non-porous surface resists dust accumulation, contributing to cleaner air quality and less frequent maintenance

In terms of maintenance, FRP chimneys require significantly less upkeep compared to conventional materials

2. Speed and Efficiency Industrial sergers operate at much higher speeds compared to domestic models, capable of stitching thousands of feet of fabric per hour. This rapid production capability is vital in a fast-paced manufacturing environment, helping meet tight deadlines.

Twin needle sewing is not limited to decorative purposes; it also plays a vital role in practical applications. For instance, sewing elastic into garments often benefits from the twin needle technique. It creates secure, flexible seams that allow garments to stretch and move comfortably. Similarly, when working on various sewing projects like curtains or tablecloths, a twin needle can ensure that seams are reinforced while adding a polished finish.

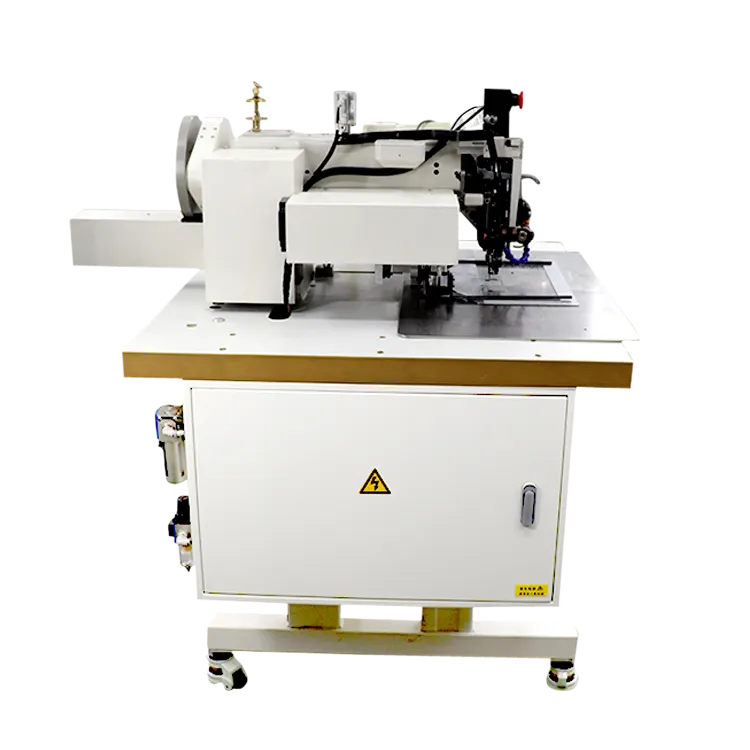

domestic special sewing machine. With features like drop feed and free-motion quilting, domestic special sewing machines offer the flexibility and control you need to tackle a wide range of sewing tasks.

Mastering Blind Stitch Upholstery

Once your project is complete, take the time to carefully inspect your work. Make any necessary adjustments and give your item a final press with the iron for a polished look. Remember, practice is key in sewing; the more you sew, the more skilled you will become.

Aria, a costume designer, shares, “I switched to a heavy-duty machine two years ago, and it’s transformed my work. I can now handle a wider range of fabrics, and the machine doesn’t falter even with constant use.”

2. The main features of the heavy material sewing machine: the heavy material sewing machine adopts the upper and lower composite feeding and the cross-lifting mechanism of the presser foot to ensure that the upper and lower layers do not shift under any stitch length within the rated range, sewing slippery, viscous sewing material and special long products. The products are neat and the stitches are beautiful; the connecting rod thread take-up mechanism increases the spindle speed; the lower feeding shaft adopts sliding bearings, which reduces the noise and prolongs the service life.

- Thread Selection Use high-quality thread to avoid breakage and ensure smooth stitching. Different fabrics may require specific thread types; for instance, polyester threads are often recommended for added stretch.

Traditional Quilting: Traditional quilting entails the creation of quilts using patterns and techniques that have been passed down through generations, such as the “Log Cabin,” “Double Wedding Ring,” and “Star” patterns. Since quilts typically consist of multiple layers of fabric and batting, a heavy-duty sewing machine must weave through these layers efficiently and produce even, durable stitches.

3. Powerful Motor Leather requires more power to sew through compared to regular fabrics. A machine with a more powerful motor ensures consistent stitching and can handle the thickness of leather.

leather jacket sewing machine

- Fashion and Apparel Designers use these machines to create garments from heavy fabrics, ensuring they can handle intricate designs without fabric damage.

To use a manual lockstitch sewing machine, one must first prepare the machine by winding the bobbin and threading the needle. Once the fabric is placed under the presser foot, the user can start sewing by pressing the pedal. The stitch length can often be adjusted depending on the project requirements, from fine seams for delicate fabrics to longer stitches for heavier materials.

Adjusting Your Sewing Machine

Heavy duty machines typically have higher maximum sewing speeds, around 1500 stitches per minute, versus 1000-1200 stitches per minute for standard machines. Again, this allows them to work through heavy fabrics more efficiently. However, heavy duty machines also tend to sew better at slower speeds, in the 500-800 stitch per minute range, for optimal control through thick seams. So they provide a wider speed range to suit the fabric.

Reduced Error and Waste

1. Powerful Motor A heavy-duty sewing machine should come equipped with a powerful motor that can easily handle tough materials like denim, leather, and canvas. Look for machines that provide a higher stitch power (measured in watts or amps) as they will be better equipped to sew through multiple layers without jamming or breaking needles.

The Long Arm Sail Sewing Machine with Puller A Game Changer for Marine Canvas Projects

In the world of leathercraft, the process of stitching leather is both an art and a science. With the advent of technology, leather stitching machines have significantly transformed how artisans and manufacturers approach this age-old craft. The integration of these machines into leatherworking not only enhances productivity but also ensures consistent quality, allowing creators to explore intricate designs that were once impractical by hand.

Its ability to handle diverse rock types, from soft to extremely hard, makes it a go-to choice for many industries Its ability to handle diverse rock types, from soft to extremely hard, makes it a go-to choice for many industries

Its ability to handle diverse rock types, from soft to extremely hard, makes it a go-to choice for many industries Its ability to handle diverse rock types, from soft to extremely hard, makes it a go-to choice for many industries Their non-porous surface resists dust accumulation, contributing to cleaner air quality and less frequent maintenance Their non-porous surface resists dust accumulation, contributing to cleaner air quality and less frequent maintenance

Their non-porous surface resists dust accumulation, contributing to cleaner air quality and less frequent maintenance Their non-porous surface resists dust accumulation, contributing to cleaner air quality and less frequent maintenance